This NEMA 14-size hybrid bipolar stepping motor has a 1.8° step angle (200 steps/revolution). Each phase draws 1 A at 2.7 V, allowing for a holding torque of 1.4 kg-cm (20 oz-in).

Special Order

Shipping from $9.90

+67 more from our supplier in 7-10 days

Our Code: SKU-002542

Supplier Link: [Pololu MPN:1209]

This NEMA 14-size hybrid bipolar stepping motor has a 1.8° step angle (200 steps/revolution). Each phase draws 1 A at 2.7 V, allowing for a holding torque of 1.4 kg-cm (20 oz-in).

This hybrid bipolar stepping motor has a 1.8° step angle (200 steps/revolution). Each phase draws 1 A at 2.7 V, allowing for a holding torque of 1.4 kg-cm (20 oz-in). The motor has four colour-coded wires terminated with bare leads: black and green connect to one coil; red and blue connect to the other. It can be controlled by a pair of suitable H-bridges (one for each coil), but we recommend using a bipolar stepper motor driver or one of our Tic Stepper Motor Controllers. In particular, the Tics make control easy because they support six different interfaces (USB, TTL serial, I²C, RC, analogue voltages, and quadrature encoder) and are configurable over USB with our free configuration utility.

|

|

Bipolar stepper motor wiring diagram. |

|---|

Our 5 mm universal mounting hub can be used to mount objects on the stepper motor’s 5 mm-diameter output shaft, and our NEMA 14 aluminium bracket offers a variety of options for mounting this stepper motor in your project.

More specifications are available in the datasheet (182k pdf).

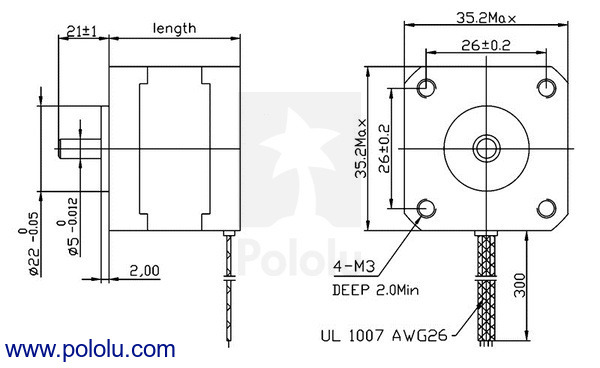

The following diagram shows the stepper motor dimensions in mm. The dimension labelled “length” is 36 mm. The output D-shaft has a length of 21 mm and a 5 mm diameter with a section that is flattened by 0.5 mm. This shaft works with our 5 mm universal mounting hub.

|

Stepper motors are generally used in a variety of applications where precise position control is desirable and the cost or complexity of a feedback control system is unwarranted. Here are a few applications where stepper motors are often found:

|

Pololu’s assortment of stepper motors. |

|---|

Note: This stepper motor is SOYO part number SY35ST36-1004A.

| Size: | 35 mm square × 36 mm1 |

|---|---|

| NEMA size: | 14 |

| Weight: | 180 g |

| Shaft diameter: | 5 mm |

| Shaft type: | 5 mm "D" |

|---|---|

| Current rating: | 1000 mA2 |

| Voltage rating: | 2.7 V |

| Holding torque: | 20 oz·in |

| Steps per revolution: | 200 |

| Resistance: | 2.7 Ohm2 |

| Inductance per phase: | 4.3 mH |

| Number of leads: | 4 |

| Lead length: | 30 cm |

Yes. To avoid damaging your stepper motor, you want to avoid exceeding the rated current, which is 600 mA in this instance. All of our stepper motor drivers let you limit the maximum current, so as long as you set the limit below the rated current, you will be within spec for your motor, even if the voltage exceeds the rated voltage. The voltage rating is just the voltage at which each coil draws the rated current, so the coils of your stepper motor will draw 600 mA at 3.9 V. By using a higher voltage along with active current limiting, the current is able to ramp up faster, which lets you achieve higher step rates than you could using the rated voltage.

If you do want to use a lower motor supply voltage for other reasons, consider using our DRV8834 or STSPIN-220 low-voltage stepper motor drivers.