These small brushed DC gearmotors can deliver a lot of power for their size. This version has a 6V brushed DC motor combined with a 195.3:1 metal spur gearbox.

Special Order

Shipping from $7.90

+25 more from our supplier in 7-10 days

Our Code: SKU-003897

Supplier Link: [Pololu MPN:3469]

These cylindrical brushed DC gearmotors are available in a wide range of gear ratios, from 25:1 up to 488:1, and they are optionally available with an additional 2 mm-diameter output shaft that protrudes 6 mm from the rear of the motor. This optional rear shaft rotates at the same speed as the input to the gearbox and offers a way to add an encoder, such as our magnetic encoder for 20D mm metal gearmotors, to provide motor speed or position feedback.

The gearmotors all have 20 mm-diameter gearboxes and 4 mm-diameter gearbox output shafts, so it is generally easy to swap one version for another if your design requirements change (though the length of the gearbox tends to increase with the gear ratio). Please see the 20D mm metal gearmotor comparison table for detailed specifications of all our 20D mm metal gearmotors. This dynamically-sortable table can help you find the gearmotor that offers the best blend of speed, torque, and current-draw for your particular application. A more basic comparison table is available below:

| Rated Voltage |

Stall Current @ Rated Voltage |

No-Load Speed @ Rated Voltage |

Approximate Stall Torque @ Rated Voltage |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|---|---|---|---|---|---|

| 6 V | 3.2 A | 560 RPM | 30 oz-in | 25:1 6V | 25:1 6V dual-shaft |

| 450 RPM | 35 oz-in | 31:1 6V | 31:1 6V dual-shaft | ||

| 225 RPM | 60 oz-in | 63:1 6V | 63:1 6V dual-shaft | ||

| 180 RPM | 75 oz-in | 78:1 6V | 78:1 6V dual-shaft | ||

| 140 RPM | 90 oz-in | 100:1 6V | 100:1 6V dual-shaft | ||

| 110 RPM | 100 oz-in | 125:1 6V | 125:1 6V dual-shaft | ||

| 90 RPM | 115 oz-in | 156:1 6V | 156:1 6V dual-shaft | ||

| 70 RPM | 125 oz-in | 195:1 6V | 195:1 6V dual-shaft | ||

| 55 RPM | 140 oz-in | 250:1 6V | 250:1 6V dual-shaft | ||

| 45 RPM | 150 oz-in | 313:1 6V | 313:1 6V dual-shaft | ||

| 35 RPM | 160 oz-in | 391:1 6V | 391:1 6V dual-shaft | ||

| 29 RPM | 170 oz-in | 488:1 6V | 488:1 6V dual-shaft | ||

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. For these gearboxes, the recommended upper limit for instantaneous torque is 125 oz-in (9 kg-cm); we strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

These motors are intended for operation at around 6 V. In general, these kinds of motors can run at voltages above and below their nominal voltages; lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

Exact gear ratio: ``(28×25×25×25×25×25) / (14×10×10×10×10×10) = bb(195.3125:1)``

The diagram below shows the dimensions of the 20D mm line of metal gearmotors (units are mm over [inches]). This diagram is also available as a downloadable PDF (183k pdf).

Dimensions of the Pololu 20D mm metal gearmotors. Units are mm over [inches]. This diagram only applies to the listed gear ratios.

The gearmotor face plate has two mounting holes threaded for M2.5 screws, and you can use our custom-designed 20D mm metal gearmotor bracket (shown in the left picture below) to mount the gearmotor to your project via these mounting holes and the screws that come with the bracket.

|

The 4 mm diameter gearbox output shaft works with Pololu universal aluminium mounting hub for 4mm shafts, which can be used to mount our larger Pololu wheels (60mm-, 70mm-, 80mm-, and 90mm-diameter) or custom wheels and mechanisms to the gearmotor’s output shaft as shown in the left picture below. Alternatively, you could use our 4mm scooter wheel adaptor to mount many common scooter, skateboard, and inline skate wheels to the gearmotor’s output shaft as shown in the right picture below.

|

These motors also work with the hex adapters included with the 120mm-diameter Wild Thumper wheels (the left picture below shows a 20D mm gearmotor while the right picture shows a larger 25D mm gearmotor):

|

|

12mm Hex Wheel Adaptor for 4mm Shaft on a 20D mm Metal Gearmotor. |

|---|

You can use our magnetic encoder kit for 20D mm metal gearmotors to provide motor speed or position feedback. Please note that this kit only works on gearmotor versions that have an extended motor shaft.

We have a number of motor controllers and motor drivers that work with these 20D mm metal gearmotors. In particular, we recommend our MC33296-based motor drivers, for which we have basic single and dual carriers and a dual-channel shield for Arduino. Our VNH5019-based motor drivers (available as single and dual carriers) also work well with these motors, and because they can handle higher currents, they will run much cooler than the MC33926 carriers. If you are looking for higher-level control interfaces, such as USB, RC, analogue voltages, or serial, consider our SMC 18v7, Jrk 21v3, or TReX Jr.

|

|

|

We have an assortment of Hall effect-based current sensors to choose from for those who need to monitor motor current:

|

|

We offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Our metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

Some of the Pololu metal gearmotors. |

|---|

| Size: | 20D × 44L mm |

|---|---|

| Weight: | 45 g |

| Shaft diameter: | 4 mm |

| Gear ratio: | 195.3125:1 |

|---|---|

| Free-run speed @ 6V: | 70 rpm |

| Free-run current @ 6V: | 200 mA |

| Stall current @ 6V: | 3200 mA |

| Stall torque @ 6V: | 125 oz·in |

| Extended motor shaft?: | Y |

| Motor type: | 3.2A stall @ 6V |

No; the information we have available for this motor can be found on its product page. However, you can approximate various additional motor parameters from the information found in the “Specs” tab.

The electrical resistance of the motor can be approximated by dividing the rated voltage by the stall current (at the rated voltage). The electromotive force constant (Ke) can be approximated by dividing the rated voltage by the free-run speed (at the rated voltage). To approximate the motor torque constant (Kt), you can divide the stall torque by the stall current.

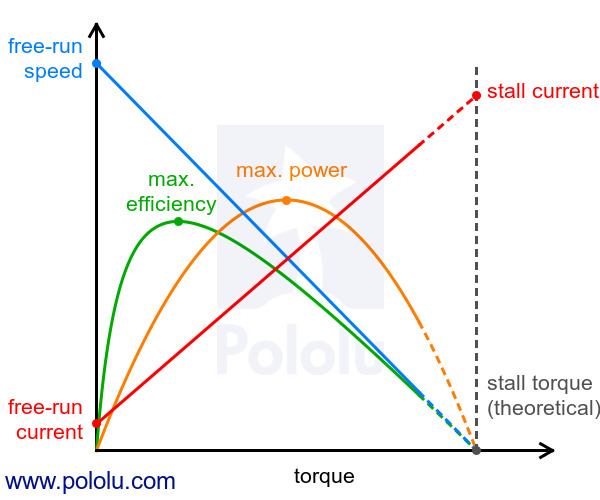

For pretty much any DC motor, the current, speed, power, and efficiency curves as a function of torque will look like those in the graph below (assuming motor voltage and temperature are constant):

|

The current and speed curves are approximately linear, and the product pages for our motors provide the approximate end points for these lines: (0 torque, no-load current) and (stall torque, stall current) for the red line, and (0 torque, no-load speed) and (stall torque, 0 speed) for the blue line.

The orange output power curve is the product of the speed and the torque, which results in an inverted parabola with its peak at 50% of the stall torque.

The green efficiency curve is the output power divided by the input power, where the input power is current times voltage. The voltage is constant, so you can divide the output power curve by the current line to get the general shape of the efficiency curve, which in turn lets you identify the torque, speed, and current that correspond to max efficiency.

There are many programs out there that you can use to generate these curves. For example, if you have access to MATLAB, you can use this customer-created MATLAB script to generate these motor plots for you from the specifications we provide for each gearmotor.

Note: A good general rule of thumb is to keep the continuous load on a DC motor from exceeding approximately 20% to 30% of the stall torque. Stalling gearmotors can greatly decrease their lifetimes, occasionally resulting in immediate damage to the gearbox or thermal damage to the motor windings or brushes. Do not expect to be able to safely operate a brushed DC gearmotor all the way to stall. The safe operating range will depend on the specifics of the gearmotor itself.